This is an old revision of the document!

Table of Contents

Input Allocation

The term input allocation describes how aggregate input demand (e.g. total anorganic N fertiliser use in Denmark) is ‘distributed’ to production activities. The resulting activity specific data are called input coefficients. They may either be measured in value (€/ha) or physical terms (kg/ha). The CAPRI data base uses physical terms and, where not available, input coefficient measured in constant prices.

Micro-economic theory of a profit maximising producer requires revenue exhaustion, i.e. marginal revenues must be equal to marginal costs simultaneously for all realised activities. The marginal physical input demand multiplied with the input price exhausts marginal revenues, leading to zero marginal profits. Marginal input demands per activity can only be used to define aggregate input demand if they are equal to average input demands. The latter is the case for the Leontief production function.

The advantage of assuming a Leontief technology in agricultural production analysis is the fact that an explicit link between production activities and total physical input use is introduced (e.g. environmental indicators can be linked directly to individual activities or activity specific income indicators, since gross margins can be calculated). The disadvantage is the rather rigid technology assumption. We would for example expect that increasing a crop share in a region will change the average soil quality the crop uses, which in turn should change yields and nutrient requirements. It should hence be understood that the Leontief assumption is an abstraction and simplification of the ‘real’ agricultural technology in a region. The assumption is somewhat relaxed in CAPRI as two ‘production intensities’ are introduced.

Input coefficients for different inputs are constructed in different ways which will be discussed in more detail in the following sections:

- For nitrate, phosphate and potash, nutrient balances are constructed so to take into account crop and manure nutrient content and observed fertiliser use, combined with gaseous losses. These balances ex post determine the effective input coefficients and regional availability of manure and overfertilisation parameters.

- For feed, the input calculation is rooted in a mix of engineering knowledge (requirement functions for animal activities, nutrient content of feeding stuff, recommendations on feed mix), observed data ex post (total national feed use, national feed costs), combined within a Highest Posterior Density (HPD) estimation framework.

- For the remaining inputs, estimation results from a FADN sample in the context of the CAPSTRAT project (2000-03) are combined with current aggregate national input demand reported in the EAA and standard gross margin estimations, again using a HPD estimation framework.

Input allocation excluding young animals, fertiliser and feed

There is a long history of allocating inputs to production activities in agricultural sector analysis, dating back to the days where I/O models and aggregate farm LPs where the only quantitative instruments available. In these models, the input coefficients represented a Leontief technology, which was put to work in the quantitative tools as well. However, input coefficients per activity do not necessary imply a Leontief technology. The allocated input demands can be seen as marginal ones (which are identical to average ones in the Leontief case) and are then compatible with flexible technologies as well.

Input coefficients can be put to work in a number of interesting fields. First of all, activity specific income indicators may be derived, which may facilitate analyzing results and may be used in turn to define sectoral income. Similarly, important environmental indicators are linked to input use and can hence be linked to activities as well with the help of input coefficients.

Given the importance or the input allocation, the CAP STRAT project (2000-2003) comprised an own work package to estimate input coefficients. On a first step, input coefficients were estimated using standard econometrics from single farm record as found in FADN. Additionally, tests for a more complex estimation framework building upon entropy techniques and integrating restrictions derived from cost minimization were run in parallel. The need to accommodate the estimation results with data from the EAA in order to ensure mutual compatibility between income indicators and input demand per activity and region on the one hand, and sectoral income indicators as well as sectoral input use on the other, requires deviating from the estimated mean of the coefficients estimated from single farm records. Further on, in some cases estimates revealed zero or negative input coefficients, which cannot be taken over. Accordingly, it was decided to set up a second stage estimation framework building upon the unrestricted estimates from FADN. The framework can be applied to years where no FADN data are available, and thus ensures that the results will be continuously used for the years ahead, before an update of the labor-intensive estimations is again necessary and feasible.

As a result of the unrestricted estimation based on FADN 1)a matrix of input coefficients for 11 input categories (Total Inputs, Crop Only Inputs, Animal Only Inputs, Seeds, Plant Protection, Fertilizer, Other Crop Inputs, Purchased and Non-Purchased Feeds and Other Animal Only Inputs) and their estimated standard errors is available. Some of those coefficients are related to the output of a certain activity (e.g. how much money is spend on a certain input to produce one unit of a product), some of them are related to the acreage of on activity (input costs per activity level).

All of the econometric coefficients were required to be transformed into an ‘activity level’ form, due to the fact that this is the definition used in the CAPRI model. Before this could be done, it seemed necessary to fill up the matrix of estimated coefficients because some estimates were missing and others were negative. In order to this we constructed a number of coefficients that were weighted averages among certain groups. These mean coefficients were the following.

- Mean coefficients of activity groups. Each activity was allocated to a certain group (e.g. soft wheat belonged to cereals). For each group we built weighted averages among the positive estimates within a group using the estimated t statistics as weights. This coefficient only existed if there was at least one positive estimate inside that group and was then used to replace the gaps inside the coefficient matrix. If that mean coefficient was not available, due to no positive estimate inside a group at all, the next type of mean coefficients became relevant:

- Mean coefficients for an activity among European regions. This second type of mean coefficients calculates weighted averages among three types of regional clusters. These clusters are Northern European States, Southern European states and all European regions. Again, the estimated t statistics were used as aggregation weights. Unfortunately, this type of averages did not fill all gaps in the coefficient matrix as there were some activities that had no positive estimate over the entire EU. For those the third type of mean coefficients was calculated.

- Mean coefficients for activity groups among regional clusters. Here we calculated for the three regional clusters the averages of the first type of mean coefficients. As even the latter are synthetic, we gave each mean of them the same weight. Fortunately there was only a small probability that this coefficient did not exist for one of the groups as this was only the case if no coefficient inside a group over the entire EU had a positive estimate, which was not the case.

Following these rules we finally got a matrix of estimated and synthetic calculated input coefficients for both, the ‘per activity level’ and the ‘per production’ unit definition2). For the synthetic one there was no estimated standard error available but we wanted to use those later on. So we assumed them –to reflect that these coefficients have only weak foundation– to have a t statistic of 0.5.

The ‘per level’ definition was only taken over if the coefficient was really estimated or if no per production unit definition did exist. To transfer the latter into per activity level definition, we multiplied them with the average yield (1985 2001) of the respective activity. The resulting coefficients and their standard errors were then used a HPD approach as a first set of priors3).

Missing econometric estimates and compatibility with EAA figures were not the only reasons that made a reconciliation of estimated inputs coefficients necessary. Moreover, the economic sense of the estimates could not be guaranteed and the definition of inputs in the estimation differed from the one used in CAPRI. Therefore we decided to include further prior information on input coefficients in agriculture. The second set of priors in the input reconciliation was therefore based on data from the EAA. Total costs of a certain input within an activity in a European Member State was calculated by multiplying the total expenditures on that input with the proportion of the total expected revenue of that activity to that of all activities using the input. Total expected revenue in this case was the production value (including market value and premiums) of the respective activity. If this resulted in a certain coefficient being calculated as zero due to missing data, then this coefficient would be replaced by one from a similar activity e.g. a zero coefficient for ‘MAIF’ would be replaced by the coefficient for ‘GRAS’

This kind of prior information tries to give the results a kind of economic sense. For the same reason the third type of priors was created based on standard gross margins for agricultural activities received from EUROSTAT. Those existed for nearly all activities. The set from 1994 was used, since this was the most complete available. Relative rather than absolute differences were important, given the requirement to conform to EAA values4).

Given the three types of prior information explained above –estimated input coefficients, data from EAA and standard gross margins , a HPD estimator has been used to reconcile the prior information on input coefficients. Accounting constraints ensure (see in “dist_input.gms”) first that gross margins for an activity is the difference between expected revenue per activity level of that activity and the sum over all inputs used in that activity and second that the sum over all activities of their activity levels multiplied with an input gives the total expenditures on that input given by the EAA. The estimation is carried out in GAMS within and run for each year in the database. Some bounds are further set to avoid estimates running into implausible ranges.

The Highest Posterior Density estimation yields monetary input coefficients for the fertiliser types (Nitrate, Phosphate, Potassium), seeds, plant protection, feeds, pharmaceutical inputs, repairs, agricultural service input, energy and other inputs. While some of these can be directly used in the CAPRI model, we need special treatments for others –e.g. fertilisers, because they are used in physical units inside the model, and feeds, since they are much more disaggregated.

Input allocation for young animals and the herd flow model

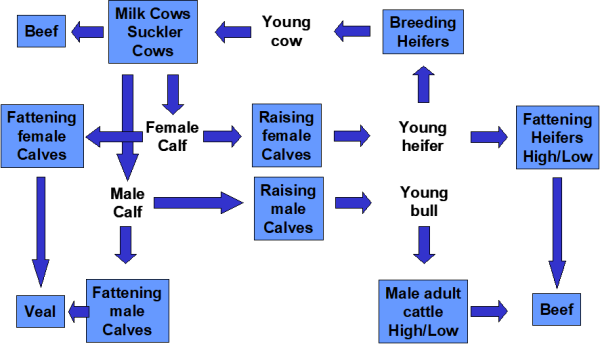

Figure below shows the different cattle activities and the related young animal products used in the model. Milk cows (DCOL, DCOH) and suckler cows (SCOW) produce male and female calves (YCAM, YCAF). The relation between male and female calves is estimated ex post in the COCO framework. These calves are assumed to weigh 50 kg at birth (see gams\feed\feed_decl.gms) and to be born on the 1st of January. They enter immediately the raising processes for male and female calves (CAMR, CAFR) which produce young heifers (YHEI, 300 kg live weight) and young bulls (YBUL, 335 kg). The raising processing are assumed to take one year, so that calves born in t enter the processes for male adult fattening (BULL, BULH), heifers fattening (HEIL, HEIH) or heifers raising (HEIR) on the 1st January of the next year t+1. The heifers raising process produces then the young cows which can be used for replacement or herd size increasing on the first of January of t+2. The table below the diagram shows a numerical example (for DK, 1999-2001) for these relationships.

Figure 5: The cattle chain

Accordingly, each raising and fattening process takes exactly one young animal on the input side. The raising processes produce exactly one animal on the output side which is one year older. The output of calves per cow, piglets per sow, lambs per mother sheep or mother goat is derived ex post, e.g. simultaneously from the number of cows in t-1, the number of slaughtered bulls and heifers and replaced in t+1 which determine the level of the raising processes in t and number of slaughtered calves in t. The herd flow models for pig, sheep and goat and poultry are similar, but less complex, as all interactions happen in the same year, and no specific raising processes are introduced.

Table 7: Example for the relation inside the cattle chain (Denmark, 1999-2001)

| 1999 | 2000 | 2001 | ||

|---|---|---|---|---|

| Male calves used in t and born in t | ||||

| DCOWLEVL | Number of dairy cows | 667,03 | 654,08 | 631,92 |

| DCOWYCAM | Number of male calves born per 1000 dairy cows | 420,72 | 438,62 | 438,26 |

| Number of males calves born from dairy cows | 280,63 | 286,89 | 276,95 | |

| SCOWLEVL | Number of suckler cows | 127,36 | 126,91 | 124,85 |

| SCOWYCAM | Number of male calves born per 1000 suckler cows | 420,72 | 411,83 | 401,61 |

| Number of male calves born from suckler cows | 53,58 | 52,27 | 50,14 | |

| Number of all male calves born | 334,22 | 339,16 | 327,09 | |

| GROFYCAM | Number of male calves produced | 334,21 | 339,16 | 327,09 |

| CAMFLEVL | Number of male calves fattened | 81,32 | 72,57 | 49,18 |

| CAMRLEVL | Activity level of the male calves raising process | 252,89 | 266,59 | 277,91 |

| Sum of processes using male calves | 334,21 | 339,16 | 327,09 | |

| GROFYCAM | Number of male calves used | 334,21 | 339,16 | 327,09 |

| Female calves used in t and born in t | ||||

| DCOWLEVL | Number of dairy cows | 667,03 | 654,08 | 631,92 |

| DCOWYCAF | Number of female calves born per 1000 dairy cows | 404,15 | 421,58 | 412,86 |

| Number of female calves born from dairy cows | 269,58 | 275,75 | 260,89 | |

| SCOWLEVL | Number of suckler cows | 127,36 | 126,91 | 124,85 |

| SCOWYCAF | Number of male calves born per 1000 suckler cows | 404,15 | 398,04 | 387,21 |

| Number of female calves born from suckler cows | 51,47 | 50,52 | 48,34 | |

| Number of all female calves born | 321,05 | 326,26 | 309,24 | |

| GROFYCAF | Number of female calves produced | 321,05 | 326,27 | 309,24 |

| CAFFLEVL | Number of female calves fattened | 26,64 | 28,74 | 18,39 |

| CAFRLEVL | Activity level of the female calves raising process | 294,41 | 297,53 | 290,85 |

| Female calves used in t and born in t | 321,05 | 326,27 | 309,24 | |

| GROFYCAF | Number of female calves used | 321,05 | 326,27 | 309,24 |

| Young bulls used in t and young bulls produced in t | ||||

| BULFLEVL | Activity level of the bull fattening process | 262,94 | 252,89 | 266,59 |

| GROFIBUL | Number of young bulls used | 262,94 | 252,89 | 266,59 |

| GROFYBUL | Number of young bulls raised from calvs | 252,89 | 266,59 | 277,91 |

| CAMRLEVL | Activity level of the male calves raising process | 252,89 | 266,59 | 277,91 |

| Heifers used in t and heifers produced in t | ||||

| HEIFLEVL | Activity level of the heifers fattening process | 64,36 | 67,25 | 68,12 |

| HEIRLEVL | Activity level of the heifers raising process | 235,45 | 227,16 | 229,4 |

| Sum of heifer processes | 299,81 | 294,41 | 297,52 | |

| GROFIHEI | Number of heifers used | 299,81 | 294,41 | 297,53 |

| GROFYHEI | Number of heifers raised from calves | 294,41 | 297,53 | 290,85 |

| CAFRLEVL | Activity level of the female calves raising process | 294,41 | 297,53 | 290,85 |

| Cows used in t and heifers produced in t | ||||

| DCOWLEVL | Number of dairy cows | 667,03 | 654,08 | 631,92 |

| DCOWICOW | Number of young cows needed per 1000 dairy cows | 332,01 | 332,5 | 327,52 |

| Sum of young cows needed for the dairy cow herd | 221,46 | 217,48 | 206,97 | |

| DCOWSLGH | Slaugthered dairy cows | 221,47 | 217,48 | 206,11 |

| SCOWLEVL | Number of suckler cows | 127,36 | 126,91 | 124,85 |

| SCOWICOW | Number of young cows needed per 1000 suckler cows | 332,01 | 332,48 | 327,52 |

| Sum of young cows needed for the suckler cow herd | 42,28 | 42,20 | 40,89 | |

| SCOWSLGH | Slaugthered suckler cows | 42,29 | 42,19 | 40,72 |

| Sum of slaughtered cows | 263,76 | 259,67 | 246,83 | |

| GROFICOW | Number of young cows used | 263,75 | 259,67 | 247,86 |

| Stock change in dairy cows | (DCOWLEVL(t+1)-DCOWLEVL(t) | -12,95 | -22,16 | |

| Stock change in suckler cows | (SCOWLEVL(t+1)-SCOWLEVL(t) | -0,45 | -2,06 | |

| Sum of stock changes in cows | -13,4 | -24,22 | ||

| Sum of slaughtered cows and stock change | 235,45 | |||

| GROFYCOW | Numer of heifers raised to young cows | 235,45 | 227,16 | 229,4 |

| HEIRLEVL | Activity level of the heifers raising process | 235,45 | 227,16 | 229,4 |

The table above is taken from the COCO data base. In some cases, regional statistical data or estimates for number of young animals per adult are available, but in most cases, all input and output coefficients relating to young animals are identical at regional and national level. Nevertheless, experiences with simulations during the first CAPRI project phase revealed that a fixed relationship between meat output and young animal need as expressed with on bull fattening process overestimates the rigidity of the technology in the cattle chain, where producers may react with changes in final weights to relative changes in output prices (meat) in relation to input prices (feed, young animals). A higher price for young animals will tend to increase final weights, as feed has become comparatively cheaper and vice versa. In order to introduce more flexibility in the system, the dairy cow, heifer and bull fattening processes are split up each in two processed as shown in the following table.

Table 8: Split up of cattle chain processes in different intensities

| Low intensity/final weight | High intensity/final weight | |

|---|---|---|

| Dairy cows (DCOW) | DCOL: 60% milk yield of average, variable inputs besides feed an young animals at 60% of average | DCOH: 140% milk yield of average, variable inputs besides feed an young animals at 140% of average |

| Bull fattening (BULF) | BULL: 20% lower meat output, variable inputs besides feed an young animals at 80% of average | BULH: 20% higher meat output, variable inputs besides feed an young animals at 120% of average |

| Heifers fattening (HEIF) | HEIL: 20% lower meat output, variable inputs besides feed an young animals at 80% of average | HEIH: 20% higher meat output, variable inputs besides feed an young animals at 120% of average |

Input allocation for feed

The input allocation for feed describes how much kg of certain feed categories (cereals, rich protein, rich energy, feed based on dairy products, other feed) or single feeding stuff (fodder maize, grass, fodder from arable land, straw, milk for feeding) are used per animal activity level5).

The input allocation for feed takes into account nutrient requirements of animals, building upon requirement functions. The input coefficients for feeding stuff shall hence ensure that energy, protein requirements, etc. cover the nutrient needs of the animals. Further on, ex post, they should be in line with regional fodder production and total feed demand statistics at national level, the latter stemming from market balances. And last but not least, the input coefficients together with feed prices should lead to reasonable feed cost for the activities.

Estimation of fodder prices

Since the last revision of the EAA, own produced fodder (grass, silage etc.) is valued in the EAA. Individual estimates are given for fodder maize and fodder root crops, but no break down is given for fodder on arable land and fodder produced as grassland as presented in the CAPRI data base. The difference between grass and arable land is introduced, as conversion of grass to arable land is forbidden under cross compliance conditions so that marginal values of grassland and arable land may be different.

The price attached to fodder should reflect both its nutritional content and the production costs at regional level. The entropy based estimation process tries to integrate both aspects.

The following equations are integrated in the estimator. Firstly, the regional prices for ‘grass’, ‘fodder on arable land’ and ‘straw’ (fint) multiplied with the fed quantities at regional level must exhaust the vale reported in the economic accounts, so that the EAA revenues attached to fodder are kept unchanged:

\begin{equation} \sum_{r,fint}\overline{FEDUSE}_{r,fint}PFOD_{r,fint} = \overline{EAAP}_{OFAR,MS}+\overline{EAAP}_{GRAS,MS} \end{equation}

Secondly, the Gross Value Added of the fodder activities is defined as the difference between main revenues (from main fodder yield), other revenues, and total input costs based on the input allocation for crops described above.

\begin{equation} GVAM_{r,fint} = \overline{YIELD}_{r,fint}PFOD_{r,fint}+\overline{OREV}_{r,fint}-\overline{TOIN}_{r,fint} \end{equation}

Other revenues may be from the nutrient value in crop residues. Next, an HDP objective is added which penalises deviations from the a priori mode.

The a priori mode for the prices of ‘grass’ and ‘other fodder on arable land’ are the EAAP values divided by total production volume which is by definition equal to feed use. The price of straw for feed use is expected to be at 1 % of the grass price.

Supports for Gross Value Added per activity are centred around 150 % of the value of total inputs as allocated by the rules and algorithm described above, with wide bounds.

Wide supports for the Gross Value Added of the fodder activities mirror the problem of finding good internal prices but also the dubious data quality both of fodder output as reported in statistics and the value attached to it in the EAA. The wide supports allow for negative Gross Value Added, which may certainly occur in certain years depending on realised yields. In order to exclude such estimation outcomes as far as possible an additional constraint is introduced:

\begin{equation} GVAM_{r,fint} \ge \overline{TOIN}_{r,fint}\overline {gvafac} \text PLATZHALTER EQUATION 37 \end{equation}

The parameter \(gvafac\) is initialised with zero so that first a solution is tried where all activities have positive GVAs. If infeasibilities arise, the factor is stepwise increased until feasibility is achieved, to ensure that estimated fodder prices are giving the minimal number of activities with negative Gross Value Addeds.

Calibration of the feed allocation

The allocation of feed to animal activities has been changed several times (like the fertiliser allocation). The most recent version has been developed 6) in the Stable Release 2 (in the following: “Star2”) project which will become also the standard version in the CAPRI trunk at the next opportunity.

General concept

In the “pre-Star2”7) implementation, based on the CAPRI model procedures, the objective in the data consolidation in tasks “build regional database” (capreg base year) and “baseline calibration supply” (capmod, baseline mode) is to cover the daily needs per animal with the available feed stuff (considering the daily feed intake capacity). In CAPRI most parameters determining the actual requirements of animals can be derived from statistics, e.g. milk yield, final live weight, daily gain, Apart from the uncertainty of statistical data, the calculated requirements can be seen as the “true” requirements in a country or region, as the differences between different animal nutrition literature sources are usually small. Nonetheless uncertainty in the data derived parameters can often lead to an over- or underestimation of the requirements in a range of 5-20% from the computed average need. This uncertainty may be taken into account when specifying the objective function for the required allocation model in a high posterior density (hpd) approach where the uncertainty on feeding requirements is expressed in terms of a standard deviation. This basic approach also underlies the “pre-star2” feed allocation. The pre-star2 feed calibration approach also considered two economic indicators that depend on the feed allocation:

- Feed costs and

- Gross margins, in particular the avoidance of negative gross margins 8)

These two criteria have been abandoned because technical plausibility was considered more important for the feed allocation than the derived value items. It may be argued that uncertainty in feed prices should not be transferred to the physical coefficients which is a consequence when considering both in the objective. Furthermore, the pmp approach of CAPRI has proven able to cope with negative margins even though it is admitted that they may not be entirely plausible.

In the pre-star2 CAPRI approach minimum and maximum bounds on specified feeding stuffs are specified to ensure technical plausibility, but to prevent infeasibilities they left considerable degrees of freedom. Additional hard constraints were for lysin and fiber contents of feed. However, a detailed analysis revealed that the purpose of these restrictions to ensure plausible feed ratios, for example regarding the relation of concentrate feed and roughage, was often missed. It has been decided therefore to skip these constraints.

The revised feed allocation methodology includes several new additional terms in its objective to capture technical plausibility beyond the animal requirements in terms of energy and protein and technical reproducibility of the calibration approach. These will be explained in more detail in the following sections.

Equations An overview of the equations used in the old and new feed allocation procedure is given in Table below. The objective function has changed significantly and more details on this will be discussed below. The equations ensuring consistency among production and consumption of feed, as well consistency across regional levels are unchanged.

Table 9: Equations used in old and new feed allocation routine

| equation | |||

|---|---|---|---|

| old | new | description | comment |

| hpdFeed_ | hpdFeed_ | objective function | changed significantly (see following section) |

| FEDUSE_ | FEDUSE_ | Balance for feeding stuff regional | needed to achieve consistency between produced feed and feed input to all animals and among regional layers |

| FEDUSEA_ | FEDUSEA_ | Aggregation to regional feed input coefficient to aggregate one | |

| FEDUSES_ | FEDUSES_ | Fixation for feeding stuff regional in calibration | |

| REQSE_ | REQSE_ | Requirements of animals written as equality | for energy ENNE and crude protein CRPR |

| REQSN_ | Requirements of animals written as in-equality | other requirements (lysine, dry matter and fibre) | |

| MINSHR_ | Maximum feed shares | Constraints on single feed stuff not used as hard bounds in new version | |

| MAXSHR_ | Minimum feed shares | Constraints on single feed stuff not used as hard bounds in new version | |

| CST_ | CST_ | Definition of feed cost from feed input coefficients and prices | Feed cost in new version only for monitoring, not in objective or constraints |

| MEANDEV_ | Definition of average deviation from requirements for all herds | oversupply by animal type was pulled against the mean oversupply. | |

| NutContFeed_ | Nutrition content in the feed aggregates supplied to an animal category | nutrient content (per kg dry matter) is part of the objective | |

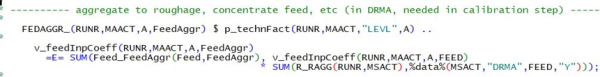

| FEDAGGR_ | aggregate to roughage, concentarte feed, etc | Defines feed aggregates from single bulks FEED | |

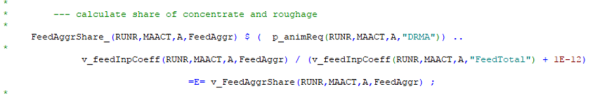

| FeedAggrShare_ | Calculate share of feed aggregates (roughage, concentrates, other) | shares of roughage and concentrate feed enter objective | |

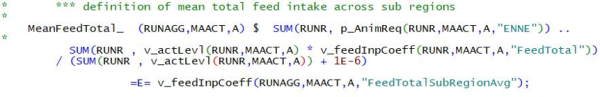

| MeanFeedTotal_ | Calculates total feed intake in DM per animal | Part of revised objective function | |

The four additional equations developed in the new feed allocation procedure are described in more detail in the following.

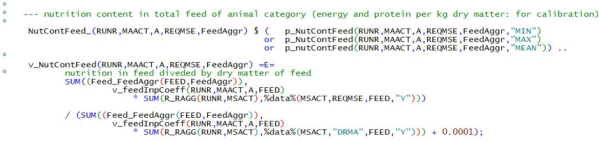

For nutrient content (energy, crude protein) in the total feed mix or in concentrate feed recommendations are frequently given in the animal nutrition literature. The equation NutContFeed_ calculates this based on the estimated feed input coefficients and the data on nutrient content and dry matter per feeding stuff. A small number is added to the denominator to avoid division by zero (e.g. while gams is searching for a feasible solution)

FedAggr_

An aggregation of specific feeding stuff to aggregates (roughage, concentrates) is done since prior shares as well as minimum and maximum shares are more often found in the literature for aggregates than for single feedstuffs. The mapping is shown in Table below. It has been specified basically by putting into the “other” category all “special” items. Therefore, straw is a component of this “other” category rather than “roughage”.

Table 10: Mapping feeding stuff to feed aggregates

| FGRA | FMAI | FOFA | FROO | FCOM | FSGM | FSTR | FCER | FPRO | FENE | FMIL | FOTH | |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| FeedRough | X | X | X | X | ||||||||

| FeedCons | X | X | X | X | ||||||||

| FeedOth | X | X | X | X | ||||||||

| FeedTotal | X | X | X | X | X | X | X | X | X | X | X | X |

One of the aggregates calculated is the total feed intake per animal. It is expected that, inspite of regional differences in fodder supply, this total feed intake is mostly a genetic characteristic of animals and hence should not vary markedly across regions. To influence this distribution in the objective, the average across regions needs to be computed.

Objective function

The objective function is extensively revised compared to the pre-star2 versions. The criteria to be optimised are now:

- coverage of animal requirements with feed

- regional variation of certain feed input coefficients

- concentration of energy and protein in feed mix

- shares of feed aggregates (roughage, concentrates, other) in total feed mix

- feed input coefficients of all FEED bulks receive prior expectations

The parameters in the objective function are partly means and imputed standard deviations AND so-called “soft” upper and lower limits. The “soft” limits increase the penalty significant when the solver picks values close to or even beyond them.

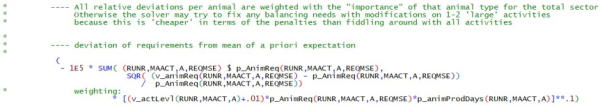

Coverage of animal requirements with feed

This part of the objective functions tries to minimize the difference between the requirements calculated from the feed input coefficients (v_animReq) and the expected (mean) requirements (p_animReq) coming from literature. Due to the weighting with number of animals (v_actLevl) and expected requirements (p_animReq) the optimal solution tends to distribute over or under supply of nutrients relatively even over all activities and regions. It has been decided to attach an exponent smaller one to these weights which strongly pulls them towards unity (see: […]

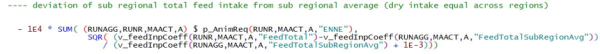

Deviation of sub regional total feed intake from regional average

As argued above, we expect that total feed intake in DRMA is mostly a genetic characteristic of animals and hence should not vary markedly across regions. Deviations of (sub-)regional feed intake from the associated regional average (NUTS1 or MS) are therefore penalised.

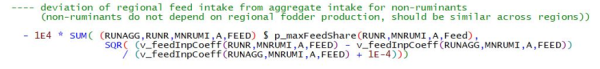

Deviations of sub regional feed input coefficients of non-ruminants from regional average

As the comment explains, non-ruminants should have a rather standardised diet across regions.

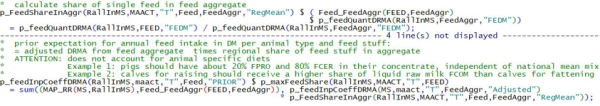

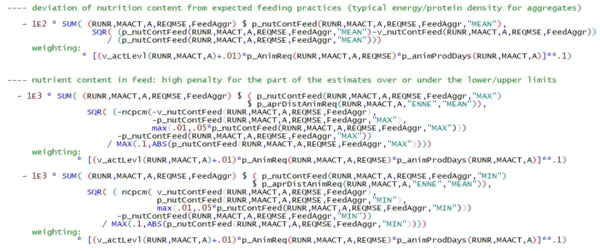

Concentration of energy and protein in feed aggregates

This part of the objective functions tries to minimize the difference between the nutrient content of feed aggregates (v_nutContFeed) and the expected nutrient (p_nutContFeed(…”MEAN”)) coming from literature or IFM-CAP. To avoid unreasonably large deviations from MEAN, lower and upper limits are introduced (MIN, MAX), where the penalty in the objective function increases significantly. The extra penalties rely on the GAMS built-in smooth approximation of the min operator (Chen-Mangasarian smoothing function ncpcm). The values for mean and upper and lower limits are presented in the table below.

Table 11: Expected nutrient content in total feed per animal category

| Energy | Crude protein | |||||

|---|---|---|---|---|---|---|

| MEAN | MIN | MAX | MEAN | MIN | MAX | |

| DCOL | 6.7 | 6.4 | 7 | 0.155 | 0.14 | 0.17 |

| DCOH | 6.8 | 6.6 | 7.2 | 0.155 | 0.14 | 0.17 |

| BULL | 6.7 | 6.2 | 7 | 0.155 | 0.14 | 0.17 |

| BULH | 6.8 | 6.4 | 7.2 | 0.155 | 0.14 | 0.17 |

| HEIL | 6.3 | 5.8 | 7 | 0.155 | 0.14 | 0.17 |

| HEIH | 6.8 | 6.2 | 7.2 | 0.155 | 0.14 | 0.17 |

| SCOW | 6.4 | 6 | 7 | 0.155 | 0.14 | 0.17 |

| HEIR | 6.4 | 6 | 7 | 0.155 | 0.14 | 0.17 |

| CAMF | 6.6 | 6.6 | 7.2 | 0.155 | 0.14 | 0.17 |

| CAFF | 6.6 | 6.6 | 7.2 | 0.155 | 0.14 | 0.17 |

| CAMR | 6.6 | 6.6 | 7.2 | 0.155 | 0.14 | 0.17 |

| CAFR | 6.6 | 6.6 | 7.2 | 0.155 | 0.14 | 0.17 |

| PIGF | 8 | 7.8 | 8.2 | 0.155 | 0.14 | 0.17 |

| SOWS | 8 | 7.8 | 8.2 | 0.155 | 0.14 | 0.17 |

| SHGM | 6.3 | 5.8 | 7 | 0.155 | 0.14 | 0.17 |

| SHGF | 6.3 | 5.8 | 7 | 0.155 | 0.14 | 0.17 |

| HENS | 8 | 7.8 | 8.2 | 0.18 | 0.14 | 0.2 |

| POUF | 8 | 7.8 | 8.2 | 0.18 | 0.14 | 0.2 |

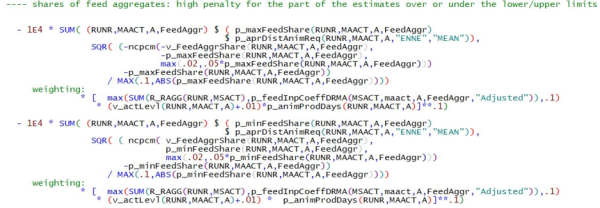

Shares of feed aggregates in total feed intake in DRMA

The shares of roughage and concentrate feed are only controlled by upper (p_maxFeedShare) and lower (p_minFeedShare) limits. The literature suggests that ruminants can digest at most 40% of concentrate feed (or at least 60% roughage), and perhaps 45% for activity DCOH. The upper and lower limits are partially taken from IFM-CAP, literature and expert knowledge of Markus Kempen (Assumed values in table 12).

Table 12: Maximum and minimum shares of feed aggregates

| Maximum shares | Minimum shares | |||

|---|---|---|---|---|

| FeedRough | FeedCons | FeedRough | FeedCons | |

| DCOL | 0.85 | 0.4 | 0.75 | 0.1 |

| DCOH | 0.7 | 0.45 | 0.6 | 0.1 |

| BULL | 0.8 | 0.4 | 0.65 | 0.1 |

| BULH | 0.8 | 0.4 | 0.65 | 0.1 |

| HEIL | 0.9 | 0.3 | 0.65 | 0.1 |

| HEIH | 0.9 | 0.3 | 0.7 | 0.1 |

| SCOW | 0.95 | 0.3 | 0.7 | 0.05 |

| HEIR | 0.9 | 0.3 | 0.7 | 0.05 |

| CAMF | 0.3 | 0.15 | ||

| CAFF | 0.3 | 0.15 | ||

| CAMR | 0.3 | 0.1 | ||

| CAFR | 0.3 | 0.1 | ||

| PIGF | 1 | 0.95 | ||

| SOWS | 1 | 0.9 | ||

| SHGM | 0.3 | 0.05 | ||

| SHGF | 0.3 | 0.05 | ||

| HENS | 0.99 | |||

| POUF | 0.99 | |||

For „other feed“ there are no lower bounds but rather low upper bounds: 10% for adult cattle, 5% for calves and sheep, 1% for pigs and 1E-6 (so near zero) for poultry.

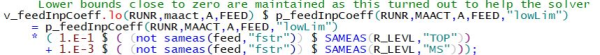

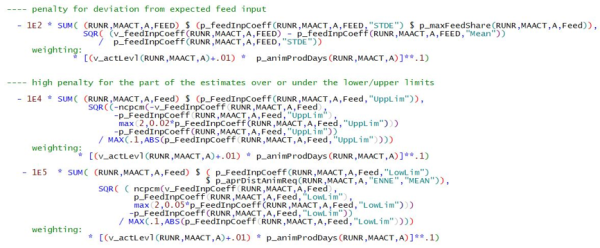

Feed input coefficients for single feed bulks

Apart from plausibility of the results a second objective of the revision has been reproducability. The previous specification essentially gave random results within the feasible set because no prior expectations had been specified. This has been revised with penalties for deviations of feed input coefficients from their assumed MEAN (specification to be explained below). However, just like is the case for the nutrient content of feed aggregates or their shares in the total, this prior information has to be considered quite imprecise which is reflected in rather low factors (1E2) attached to these terms. The penalties are increased if the solver tries to approach or exceed “soft” lower or upper limits. As the lower limits also turned out useful to prevent the solver from ending up in infeasible corners a higher factor has been attached to them (1E5).

It should also be reported that in many cases of infeasible solutions encountered in the extensive testing of this and previous specifications the last iteration result reported from the solver had often all feed input coefficients for some animal type zero or near zero. To avoid these cases the solution attempt starts with hard lower bounds:

In case of infeasibilities after x trials these are removed:

This procedure led to an acceptable or at least considerably improved stability of the feed calibration in tasks “build regional database” as well as “baseline calibration supply models”.

Priors for feed input coefficients

The priors for feed input coefficients are specified in a new include file capri\gams\feed\fedtrm_prior.gms:

The shares of feed aggregates in the diets of animal types may build upon recommendations from the literature (see the previous section). They are adjusted to be in line with the statistical ex post data or the baseline projections, giving the “adjusted” aggregate feed input coefficients shown in the code snippet above.

However, feed recommendations do snot exist for single feedstuffs because these are easily substitutable. Stability of the feed calibration requires however some priors. A simple default assumption made has been therefore: the composition of feed aggregates in terms of their components is the same for all animals (corresponding to the regional average). This is evidently a simplification such that the penalties for deviations from these priors have been set rather low to achieve both the desired stabilization effect while not competing too strongly with other components of the objective.

Nutrient contens and requirements

For the nutrient contents and requirement functions comparisons with IFM-CAP showed a good consistency such that the pre_star2 specifications were retained.

Calibration of PMP terms

The calibration of pmp terms for feeding coefficients is unchanged. But the constraints of minimum and maximum shares of feeding stuffs and some contents (fibre, lysin, etc) have been removed. The pmp terms have therefore a considerably increased role in simulations: Whereas the feed mix was so far steered by technical constraints, at least to a significant extent, all of these are gone except the equality constraints on feed energy and protein. The feed mix in simulation is therefore critically determined by the feed related pmp terms. In case of undesirable simulation behaviour it might be considered to include at least bounds for the total feed intake in terms of dry matter where feed recommendations apparently provide some bounds for plausible values.

Input allocation for fertilisers and nutrient balances

In the following section, the existing environmental indicators in CAPRI, planned and already achieved improvements, and possible further extensions are briefly discussed. It should be noted that CAPRI is basically a regionalised agricultural sector model, thus concentrating on the modelling of aggregated reactions of agricultural producers and consumers to changes in long term shifters as technical progress, income changes and CAP programs. Most indicators are rather robust pressure indicators and can be calculated easily based on fixed parameters approaches from the endogenous variables of the regional aggregate supply models. Accordingly, economic (dis)-incentives can be linked to the pressure indicators or further passive indicators can be introduced or the current ones changed easily.